Who says you can’t mix business with family?

Read Industrial – formerly known as Direct Supply and L Read and Son Ltd – has manufactured, serviced, and installed milking machines for New Zealand’s dairy industry for a century. But more than that, there are now five generations of this family involved in one of New Zealand’s last family-owned and operated milking machine manufacturing companies. Read Industrial is perhaps historically best known for its Read slide pulsator. There are arguably more cows milked in New Zealand on these simple, effective and durable pulsators than any other brand.

100 years…..

Celebrating 100 years in business.

Read Industrial is based in Rangiora. Only 30 minutes from Christchurch. It employs 55 people and remains unphased by multi-national companies working competitively within New Zealand’s busy dairying landscape. There are 17 Read’s dairy dealers throughout the country. It is also on the automation train, and it remains a cutting-edge choice for its dairy customers.

Read Industrial has also managed to juggle its humble, family-based approach with a determined additional push into general-purpose engineering, fabricating and casting componentry. There is not much that this engineering company cannot do.

It has three foundries on-site, it manufactures and supplies irrigation components to around 144 stores throughout the country & overseas. Other works include casting batch parts for other businesses, including jet boat impellers and high-end bespoke artworks.

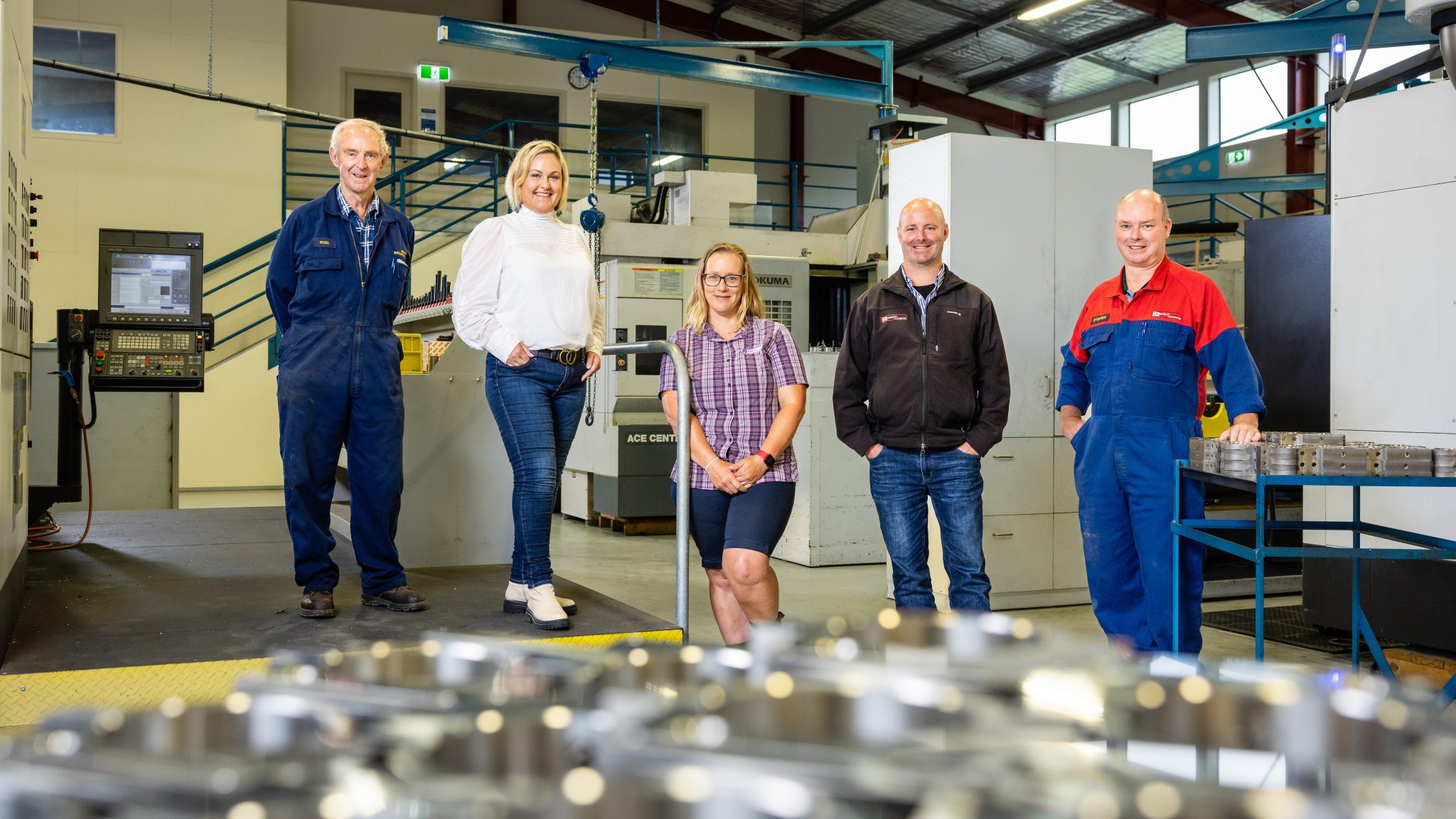

Strength in family

Its 79-year-old patriarch, Noel, and his wife, Colleen, continue to inspire and amaze their family. The humble and kind methodology Noel is well-known for has affectionately been dubbed “the Read way”. Noel defies Father Time and brings knowledge, forward-thinking and patience to what is increasingly a support role. However, he is at the factory by 7am every day, and as long as he is “home to see the news”, he’s happy. Sons Steve (and wife Jenny) and Phil (and fiancée Lisa McKenzie) all work shoulder-to-shoulder in the business, along with Steve and Phil’s sister, Tania. Their children are now also taking on roles. Both Steve (Factory Manager) and Phil (Sales Manager) have worked in every aspect of the business and are as comfortable in overalls as they are sitting in the office. They have also been branded with the Read’s likeability chip, and credit much of that to their parents.

Noel and Colleen’s four children grew up amongst approximately 30 foster children who were welcomed to the Read’s family home at different times – mostly for short stays – but some spent up to 18 years with the family. That sense of belonging is equally extended to their customers and to their staff. They recently had three generations of one family working in the company. They also employ the grandson of the owners of the first dairy shed they built in Kaikoura for the Harnett family. And, some of their customers are themselves the fifth generation of their own families to deal with Read’s.

Lisa sums it up best, saying, “I think our staff are part of the Read legacy in that it’s not only a family business – but…a family’s business.”

Fabrication and foundries bring self-sufficiency

The passion to manufacture or build much of what they need in-house has buffered Read Industrial against the supply interruptions its other counterparts deal with every day. “Having that control in the foundry has become very powerful in the last few years,” Steve said. “To not have to out-source things is very important to us.”

Phil adds, “We also invest heavily in stock that is held on-site here. Most accountants would probably have a fit if they saw what we hold. But, that’s what has kept us going in the last two years. There is still not much wastage here either. Everything is kept because it might have another use. It can often also be re-cycled through the foundry. We get a lot of farmers looking for things, and they go to Noel or Steve. Noel loves going hunting for them.”

Automation and international

Moving forward, automation is the word on everyone’s lips in order to stay ahead of labour and environmental challenges. There is also a move towards milking sheep, goats and even deer as well as a number of dairies for raw milk sales. The additional steel-work needed for automated dairies has also created manufacturing energy for the Read family. Read Industrial has never actively pursued international work, but it has completed works in 10 countries, including the United States, and the United Kingdom. That work has often been generated by young international travellers, who have worked on dairies in New Zealand and returned to their homes having experienced ‘the Read way’.

Quality remains its hallmark

“Customers can only buy cheap so many times in a row,” Phil said. “Just because ours is simple, doesn’t mean it’s necessarily cheap. Because in the long run, quality is best, and that’s what stands the test of time.”

“They make it easy for me”

Camden Group – named after a London flat brothers Leo and John Donkers lived in – owns and operates six large-scale dairy farms on the Central Canterbury Plains, around 60km south of Christchurch in New Zealand. Leo Donker’s relationship with Read Industrial stretches back five decades to their original family farm at Oxford. “It’s not only the family, it’s the relationship the Read family has with their staff that makes it easy for me,” Leo Donkers said. “Because they have so many long-term staff that know the business and that are passionate about it, we get a continuity of service that not only comes from the top of the business, but which also carries through to its technicians and service people. “That’s why they have been our preferred supplier for all our milking plants. We’re very happy with the product, the service and the relationship we have with Philip, Steve and Noel.”

Careers available

Read Industrial prefers to employ locally and Phil says they remain open to local talent. “We’ve always struggled to get people coming into our business that see it as a real career. I don’t see what we do as any different to being an electrician or a mechanic. We need skilled staff, and this industry should be respected as such,” Phil said.

While it’s been 100 years since the business was launched from a Papanui garage – and more than five decades since its move to Rangiora (1965-1966) – Reads remains a rare commodity in a fast-paced world.

A time-honoured business that has never wavered from its course to serve and to support its clients.

“Established in 1922” Find out more about our history >>>